Secure Your Workflow: Best Tapes for the Job

Plate mounting is a high volume activity in busy pressrooms. Accuracy, confidence of the adhesion and ease of periodic re-positioning is critical to getting every job out the door on time with quality printing and consistent results.

tesa Softprint® Secure

tesa Softprint® Secure

The quality of your plate mounting tape has a huge impact on the quality of the job you produce. The tape you choose to mount printing plates can result in a noticeable difference in productivity over time, and have an instant effect on print results. Bill Enright, better known as Dr. Flexo, Mark Andy’s resident expert on consumables and pressroom supplies, says it best, “Tapes are not all created equal and converters should try some of the different variations to find out what’s going to give them the best performance.”

Process Improvement

The printing industry is constantly changing and requires manufacturers to keep up with those evolving needs. Printers are expected to produce high-quality results on a daily basis, and brand owners expect perfect labels and packaging every time. With new technology and new press features comes the need for new and improved printing processes. Job changeovers and downtime are important to consider- machines are running at higher speeds and halting production results in higher costs. Tapes that promote reliable and easy mounting, dependable print processes, and consistent results are essential to today’s flexo printing.

According to Bill Enright, application engineer with Mark Andy, both the quantity and quality of available tapes has increased in recent years. “There have been a lot of advancements in stickyback tapes and adhesive systems,” Enright relates. Because of this, printers and converters who may have been using a specific type of tape over a number of years may be best served by trying some new combinations to see if they can improve their results. “Tapes are improving,” says Enright, “and the manufacturers’ goal is to improve the process for converters, so exploring new product offerings can often lead to better results.”

Unscheduled Stops

Mistakes that occur during the plate mounting process have an instantaneous effect on the quality of the job being printed, not to mention the output of sellable product. Common mistakes require the operator to stop the press unexpectedly to maintain a level of quality control with the product being printed.

Unscheduled stops ultimately result in insufficient performance, reduced productivity, and a loss of profitability. However, having to stop your press over and over doesn’t just result in wasted time- it also contributes to wasted material. Eliminating waste doesn’t just save on the job at hand, either. Waste reduction means spending less on additional substrate, ink, splicing tape, and other pressroom supplies over time, all of which can add a dent to your bottom line.

Choosing a tape with an adhesive system that ensures process security and mounting time optimization ultimately removes the risk of unscheduled stops and keeps jobs running smoothly.

Issues with Plate Lift

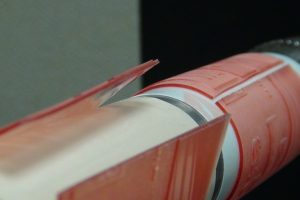

Plate lift is a fairly common issue for most converters, but it doesn’t have to be. Plate lift occurs when the edges of the printing plate lift away from the tape, either due to ink between the plate and tape or from cleaning solutions dissolving the tape’s adhesive. This can also happen if plates are not properly cleaned.

an example of plate lift

If issues with plate lift go unnoticed, jobs begin to run out of register, quality of print jobs becomes harder to control, and you end up throwing out more than you have sellable product. In the long term, that loss of profitability can mean losing the capital necessary to improve processes, grow with new technology, and propel your business forward. In the short term, plate lift causes frustration both with press operators and customers. Having issues on-press while a customer is waiting for their order may result in missed deadlines.

The Solution

Label and packaging printers face many challenges to maximizing their process efficiencies without the loss of quality. Reducing downtime and waste created in prepress processes is essential as is the ability to work at higher press speeds. Consequently identifying technology that improves these functions is a necessity to every profitable pressroom today.

Dr. Flexo’s tesa® Tape Showcase

tesa Softprint® Secure is designed to handle the major challenges for narrow web printers: plate lift, downtime, and longer run lengths. With the newly developed adhesives on both the plate roll/sleeve and plate side of the double-sided foam tape series, it effectively prevents plate lift on small repeat cylinders and sleeves while maintaining a strong, secure bond. Softprint® Secure plate mounting tapes are the ideal solution for faster printing speeds and longer print jobs as well as suitable where plates are mounted with minimal seams. Securely holding down the plates leads to less edge-lifting which in turn results in less downtime and waste.

Additionally, tesa Softprint® Secure offers you the most for your money with 9% more material per roll. On average, customers saved 33% when switching to tesa from their current brand. Let our technical experts assess the right tesa Softprint® Secure tape for your job mix. Learn more here.